Running a functional and productive commercial electrical system depends on having the right components installed in the right configuration and optimizing them for peak performance. At Power Products & Solutions, we will help you manage your electrical system with some facts on what the major system components are and what sets them apart.

Jump to:

- Get to Know Your Components

- Comparing Low-Voltage Switchgear vs. Switchboards

- Know the Warning Signs

- Contact Us for Professional Maintenance and Testing Services

Get to Know Your Components

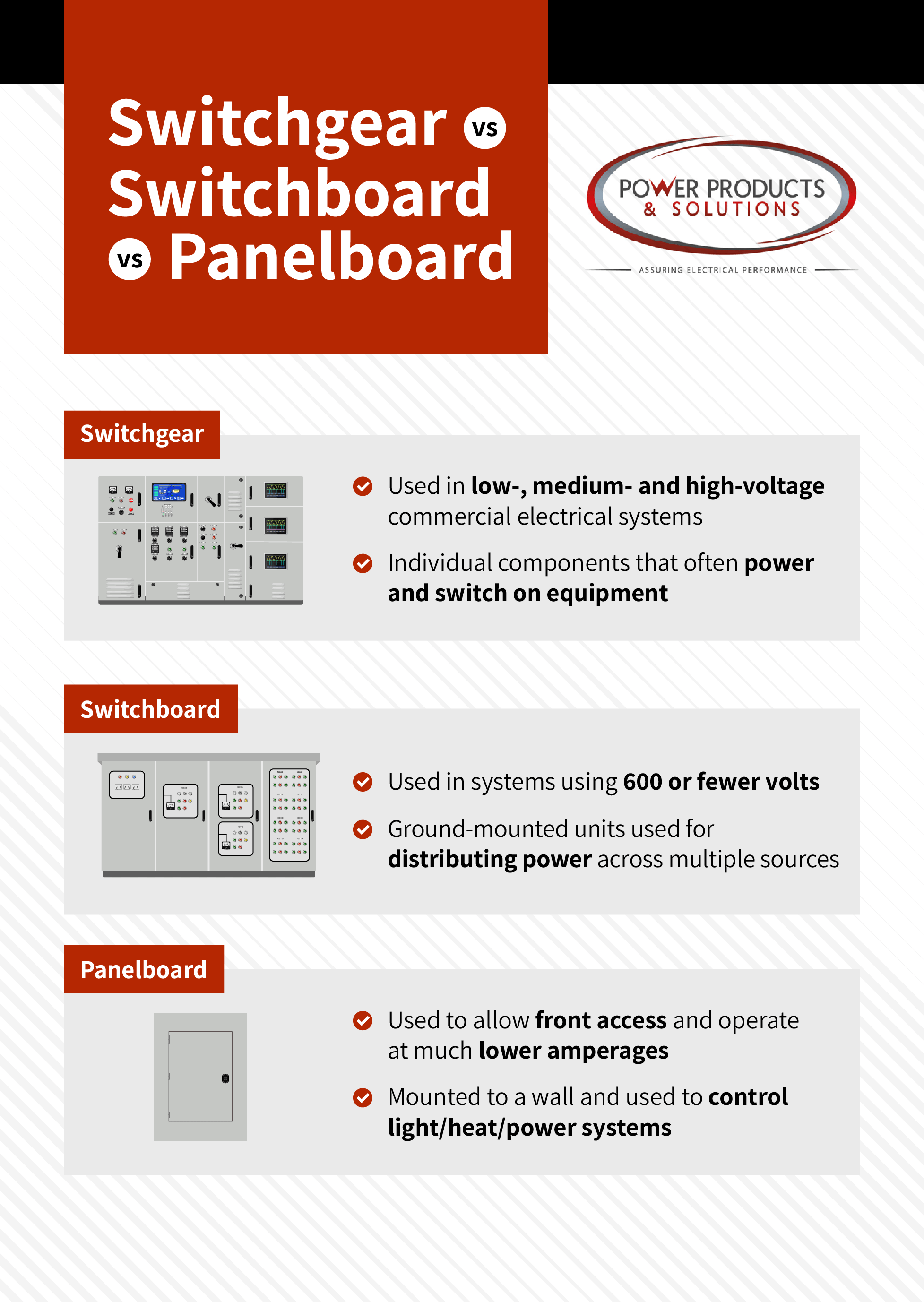

A great method for understanding the differences between switchgear, electrical switchboards and panelboards is to first see what makes them unique.

What Is Switchgear?

Switchgear is used in low-, medium- and high-voltage commercial electrical systems. Switchgear consists of individual components that often power and switch on equipment like transformers, generators, power networks and motors. A system can also use switchgear to identify faults and interrupt the electrical circuit before an overload or anomalous signal causes damage.

What’s included in a switchgear setup will vary based on system requirements. Switchgear made for protection will typically have a fuse, circuit breaker or lightning arrester. Units made for power control will often have devices like relays, current transformers and control panels to monitor and control equipment. Appropriately rated switchgear is required at every switching point in a network.

What Is a Switchboard?

One of the primary differences between switchgear and electrical switchboards is that switchgear are individual components and switchboards represent a set. While switchgear is for low-, medium- and high-voltages, switchboards are for systems using 600 or fewer volts. Switchboards are ground-mounted units used for purposes like distributing power across multiple sources.

Switchboards are another part of your system that is purpose-built and often employed along with equipment like a panelboard, transformer or other connected machinery. Configurations vary, but in most cases, switchboards have devices like switches, frequency gauges, synchroscopes, buses, monitoring devices and other electrical controls installed on one or both sides.

What Is a Panelboard?

Panelboards are electrical distribution systems that share many of the same functions as switchboards but have several distinct differences that set them apart. The most apparent difference between panelboards and switchboards is that a panelboard mounts to the wall. They only allow front access and operate at much lower amperages, typically topping out at 1,200 A.

A panelboard essentially manages commercial electrical systems. In most applications, it is intended for use with systems rated for up to 600 volts, but more robust ones are available for special circumstances. They have multiple purposes based on design and layout and are most often employed to control lighting systems, building heat and other critical power circuits.

Comparing Low-Voltage Switchgear vs. Switchboards

In many applications, you can perform the same functions using low-voltage main switchgear as a switchboard — they are often confused for each other in design and in conversation. Both are usually appropriate for the job and code-compliant. Still, each has advantages that will make one the better option:

- Low-voltage switchgear: Switchgear has a larger footprint. It is the more capable option, and professionals often use it for industrial applications, including round-the-clock manufacturing, data centers, medical facilities and other demanding functions.

- Switchboards: Switchboards are smaller and generally more affordable than switchgear. They are often applied to small to mid-sized commercial applications like office buildings, retail centers, schools and warehouses.

Know the Warning Signs

Another way to compare switchgear vs. switchboards vs. panelboards is to understand what they are trying to tell you when they are faulting out. These components all play vital roles in power distribution and management. If one is going bad, you can often tell based on these signs:

- Panelboards: Most panelboard failures occur due to wiring malfunctions, overload and age. Common signs include power fluctuations, frequently tripping breakers and burning smells.

- Switchgear: Humidity, dust, smoke, water, motion and more can cause switchgear to fail, leading to partial discharges, arcing or failures.

- Switchboards: Switchboard failures are often caused by overloads and outdated equipment. Signs to look for include a burning odor, tripped breakers and a high number of blown fuses.

Contact Us for Professional Maintenance and Testing Services

There’s much more to explore in comparing panelboards vs. main switchgear vs. switchboards — and even more involved in maintaining them. Trust the service and care of your components with experienced professionals.

At Power Products & Solutions, we have over three decades of experience providing commercial electrical solutions to businesses and facilities of all sizes nationwide, including 24/7 emergency service.

If you’re ready to take advantage of reliable testing and maintenance services, call us at 704-573-0420, fill out our contact form, or visit one of our three Southeastern US locations to learn more and schedule a consultation. For emergency assistance, please dial 704-776-0101.