Looking to modernize your facility’s electrical systems? If you’re noticing signs of wear and deterioration to your circuit breakers, a retrofit can be a great option compared to overhauling an entire electrical system. A simple upgrade can improve the overall reliability and safety of your system.

In this post, we’ll outline what goes into circuit breaker retrofitting before you schedule service.

What is a Circuit Breaker Retrofit?

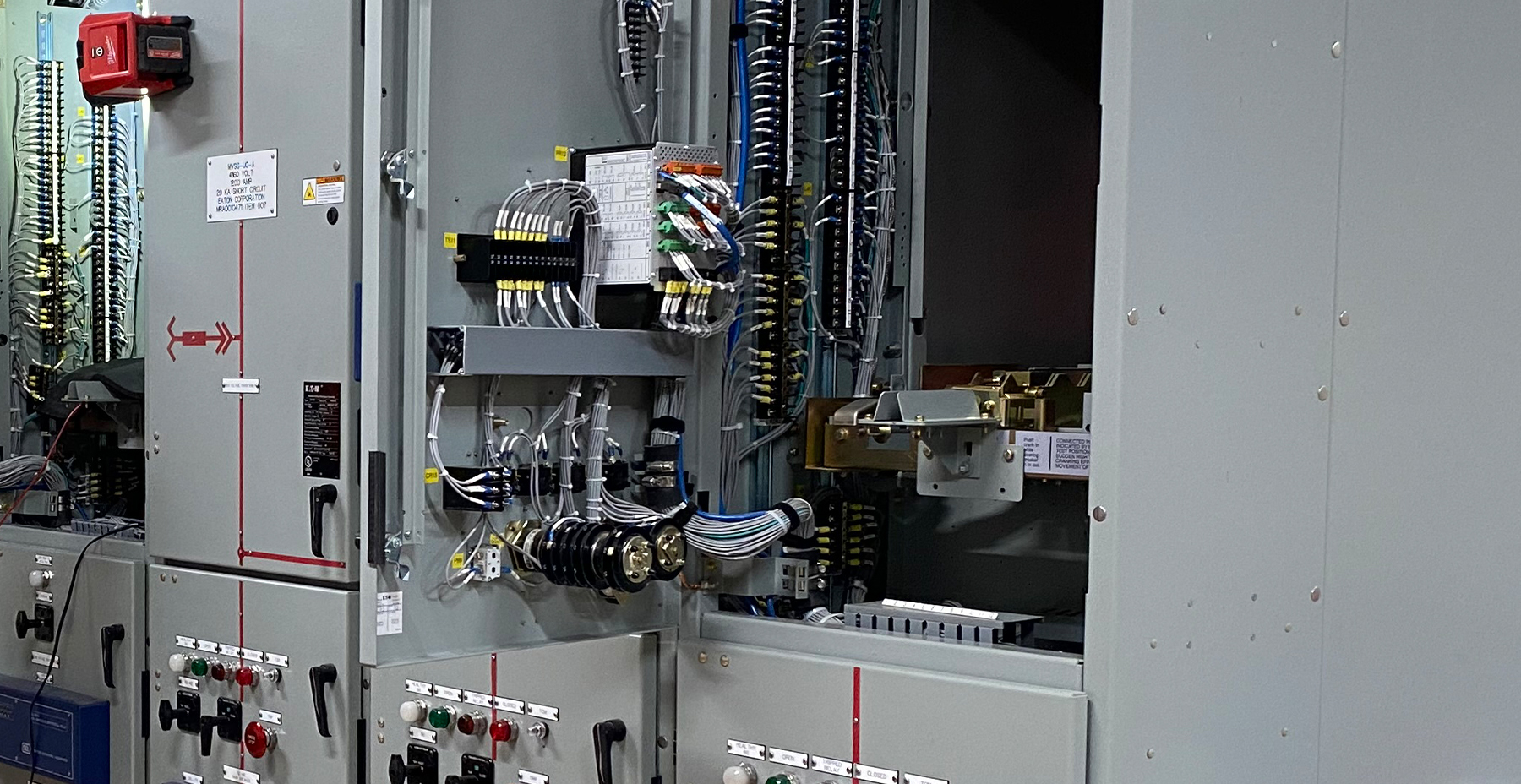

A circuit breaker retrofit involves upgrading or replacing the breaker with newer technology without overhauling an entire electrical system. Retrofitting circuit breakers and related equipment is common in facilities with a lot of older or aging infrastructure because it can help improve or extend the lifespan of these systems.

A retrofit may involve adding features like remote monitoring devices, protective relays, or communication modules. An MV retrofit often involves upgrading electromechanical relays to solid-state relays.

Why Retrofit a Circuit Breaker?

A facilities manager may retrofit existing circuit breakers for safety reasons, to reduce operational costs, or to improve the reliability and performance of existing systems.

Instead of overhauling or replacing critical systems, you can simply retrofit circuit breakers, switchgear, and other equipment with modern components.

3 Benefits of Commercial Circuit Breaker Retrofitting

1. Extending the Lifespan of Aging Infrastructure

Since many facilities rely on older circuit breaker systems installed decades ago, these systems can experience issues like:

- Deteriorating insulation due to heat, moisture, or stress

- Outdated control mechanisms

- Worn-out contacts

- Mechanical and current path adjustments that are out of tolerance

For example, a facilities manager may replace outdated electromechanical trip units with solid-state units to enhance performance, accuracy, and monitoring.

2. Greater Efficiency and Cost Savings

Aside from replacing older breakers with new equipment, retrofitting can also help improve the efficiency of older units. By adding modern features like load shedding or peak demand capabilities, you can save on energy costs with a simple upgrade.

3. Increased Adjustability and Communication with Systems

Facility managers that retrofit breaker components like solid-state trip units, for example, also have greater flexibility in adjusting settings like:

- Trip thresholds

- Time delays

- Optimizing breaker performance for different operating conditions

With upgraded components in modern trip units, managers can also access real-time monitoring for the breaker and even analyze trip histories, levels, fault trends, and other important data points.

Thanks to modern trip units or sensors like current transformers (CTs) or voltage transformers (VTs), monitoring and proactively scheduling maintenance is much easier since this data can be collected and acted on.

While visual inspection and testing are always important, newer retrofitted components can provide new communication capabilities by integrating with supervisory control, data acquisition systems (SCADA), or building management systems.

What’s the Difference Between a Breaker Retrofill vs. Retrofit?

While these terms are often used interchangeably, a retrofill involves only replacing obsolete components with newer ones. A retrofill typically involves replacing the breaker cubicle’s internal components, including the circuit breaker.

Retrofitting, on the other hand, can include broader modifications like adding supplementary components like communication or monitoring devices that enhance performance, safety, or efficiency. Both retrofilling and retrofitting can help save on costs compared to replacing an entire system.

Schedule Breaker Retrofitting with a NETA-accredited Company

To stay compliant with standards outlined by organizations like the IEEE (The Institute of Electrical and Electronics Engineers), OSHA, or the NFPA (National Fire Protection Association), you must always trust certified professionals to handle your circuit breaker repair and maintenance.

At Power Products & Solutions, we’re a trusted NETA-accredited organization with experts specializing in retrofitting, testing, terminations, and various industrial and commercial testing services.

We can help you design a retrofitting or maintenance plan tailored to your facility today.

Contact Us today to schedule service or for a free quote. We look forward to assisting you!

Need to Schedule Service or Testing at your Facility?

Power Products & Solutions is a NETA-accredited business ready to handle all your electrical testing and maintenance needs.