Safety hazards are present in almost every job, and you need a plan to keep employees safe, especially in a commercial setting where there may be electrical hazards in the workplace.

Here are 5 common electrical hazards you should be aware of, and what you can do to ensure you’re not putting anyone at risk.

1. Overloaded Power Strips or Outlets

Power strips and outlets are designed with a predetermined electrical level they can support that employees should be aware of; it’s a good idea to have a corporate policy on this topic. For example, multiple high-voltage devices on a single power strip can cause a fire.

This overload also includes plugging one power strip into another to increase available device accommodation. To be safe, check the wattage of your power strip or outlet and the devices you are plugging in to ensure they can support the load.

2. Outdated or Faulty Wiring

Because wiring for electrical devices is often hidden, we can forget about it until it is too late. If outdated or faulty wiring is overworked, it can spark and catch fire.

Here are a few signs that your equipment wiring may need to be updated or fixed:

- Frequent breaker trips – If you’re experiencing frequent breaker trips, your wiring may be overloaded and not designed to handle the demand

- Flickering lights – This can be caused by several factors like loose wiring or connections

- Equipment is warm to the touch – If outlets or switches are warm to the touch, they should be inspected immediately to avoid dangerous electrical fires.

3. Incorrect Light Bulb Wattage

Like overloaded power strips, you should also avoid using light bulbs that are too strong or not rated for light fixtures or ceiling lights.

Ensure the light bulb wattage matches or is less than the maximum wattage on the light socket to prevent electrical hazards. Using bulbs not rated for use can void the warranty on light fixtures throughout your facility should damage occur.

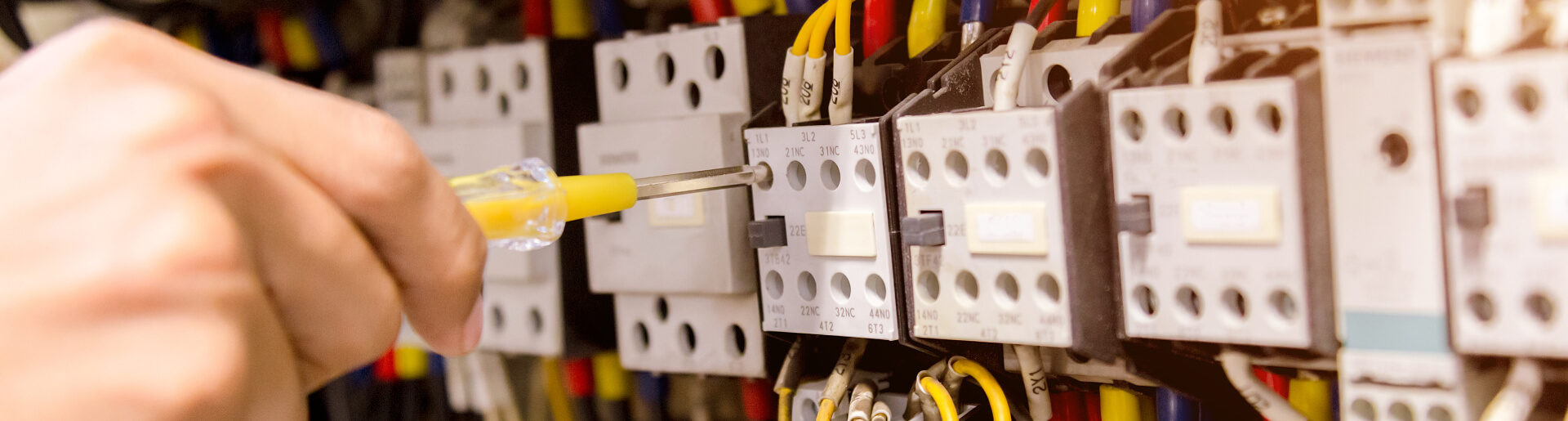

4. Exposed Electrical Wiring and Parts

Make sure your facility doesn’t have exposed electrical equipment or wiring, both inside or outside; this may include electrical components in unfinished spaces, or broken exterior lighting components.

Exposed electrical components simply adds unnecessary liability in the workplace, and increases the risk of electrical shock if employees get too close.

Be sure the needed repairs are conducted by a professional organization like Power Products and Solutions who can provide qualified technicians and engineers who can diagnose, repair, and service your workplace.

5. Damaged Equipment

Stay alert for anything that seems wrong with the equipment you use daily. Note cracks, breaks and abrasions on the wires or equipment and notify your supervisor. In the meantime, take the equipment out of service to keep co-workers safe.

Schedule Power Safety and Reliability Service With Power Products & Solutions

Don’t put off checking and testing for potential electrical hazards until it’s too late—and always seek professional guidance from certified electrical safety technicians.

Contact Power Products and Solution today for a comprehensive audit and a variety of electrical testing services. Our NETA Certified technicians can provide a variety of electrical testing services to keep your organization safe, including:

- Acceptance and maintenance testing

- Cable testing

- Electrical grounding and bonding testing

- and much more!